NYC Lead Removal Contractors-- Get Safe and Reliable Services

NYC Lead Removal Contractors-- Get Safe and Reliable Services

Blog Article

Best Practices for Guaranteeing Safe and Extensive Lead Infraction Reduction

Resolving lead violation abatement calls for a multi-faceted technique to guarantee both security and conformity. It's the last clearance process, involving extensive examinations and research laboratory testing, that genuinely validates a lead-free atmosphere, ensuring long-term security. Exactly how do these practices interconnect to assure comprehensive lead reduction?

Preliminary Evaluation

Carrying out a preliminary assessment is a crucial very first action in lead violation reduction. This phase encompasses an in-depth assessment of the residential or commercial property to determine the existence, extent, and particular places of lead-based hazards. Qualified specialists, such as qualified lead assessors or run the risk of assessors, must carry out a thorough site inspection, making use of tools like X-ray fluorescence (XRF) analyzers to precisely discover and measure lead focus in paint, dust, soil, and water.

The analysis needs to likewise include a testimonial of the structure's background, previous reports, and any type of issues or wellness concerns reported by owners - Lead Removal Contractors. Recording the findings diligently is necessary, as these records develop the basis for developing a reliable reduction method. A comprehensive analysis likewise involves tasting and research laboratory evaluation, which are important to validate the visibility of lead and guide succeeding actions

In addition, it is imperative to interact the results transparently to all stakeholders, including property owners, tenants, and regulative authorities. By ensuring that the preliminary evaluation is performed with precision and rigor, experts can lay a strong structure for a targeted and effective lead abatement process, eventually safeguarding public health and wellness and making certain conformity with regulatory criteria.

Proper Control

Correct containment is important to prevent the spread of lead pollutants during abatement activities. Efficiently managing containment minimizes the risk of lead dust and debris migrating to non-work areas, consequently guarding both the setting and people outside the instant job zone. To accomplish proper containment, an airtight obstacle of plastic sheeting need to be developed around the workspace, making certain all seams and sides are safely secured. Lead Removal Contractors. This obstacle needs to prolong from flooring to ceiling and be taped to avoid any leakages.

Routine evaluations of the containment area are essential to inspect for breaches or weaknesses in the obstacle. Any kind of identified problems ought to be quickly dealt with to maintain the honesty of the containment. By adhering to these techniques, reduction tasks can efficiently control lead contamination and alleviate affiliated wellness dangers.

Worker Protection

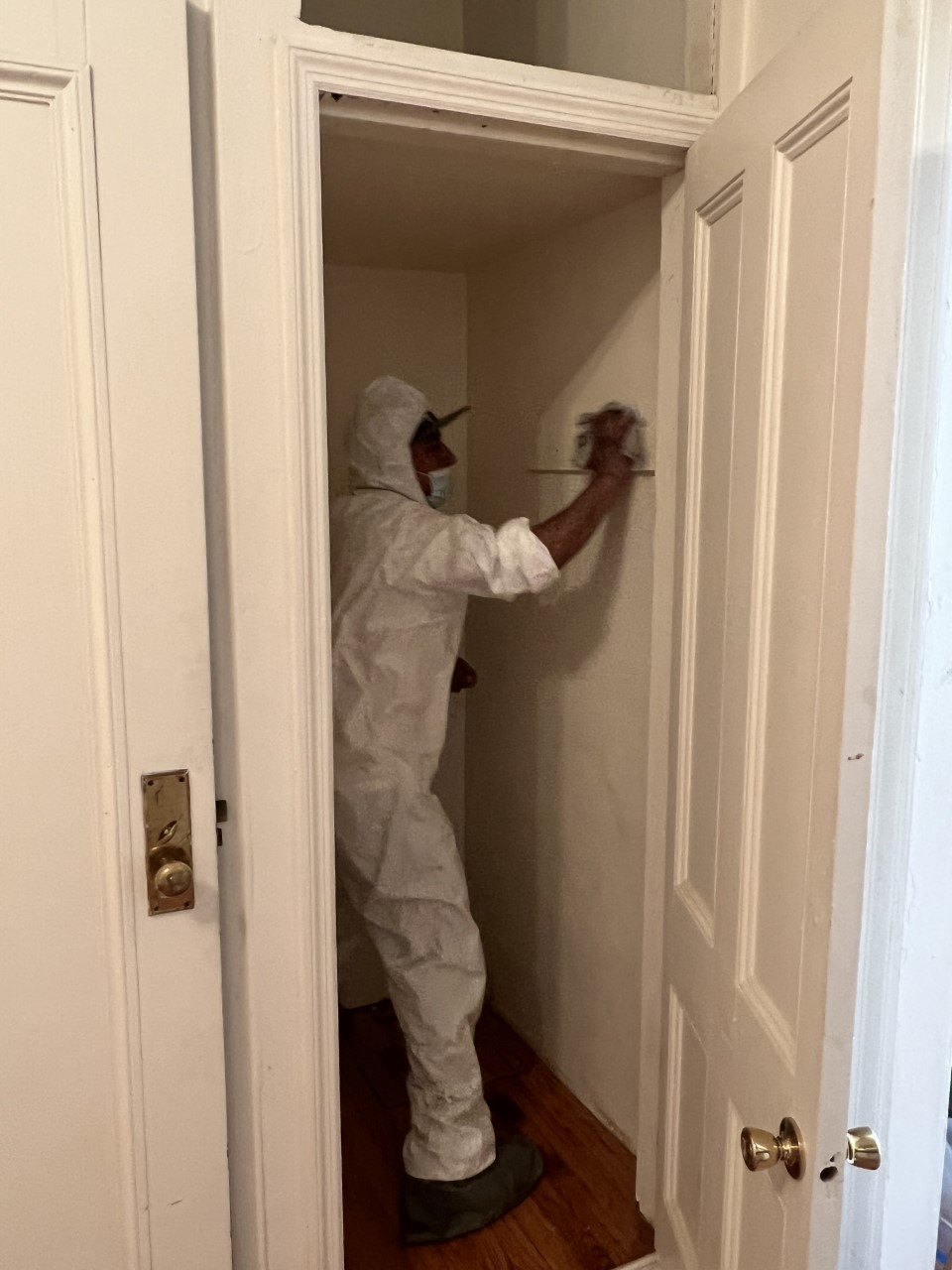

Ensuring worker security is extremely important during lead reduction projects to avoid occupational direct exposure to dangerous lead fragments. Crucial actions include the use of personal safety tools (PPE) such as respirators, gloves, and full-body matches particularly designed to block lead dust and fumes. Employees need to undergo detailed training on the proper use and maintenance of PPE, including fit testing for respirators to ensure maximum effectiveness.

Design controls, such as regional exhaust air flow systems, are crucial in reducing airborne lead concentrations in the workplace. Management controls should also be carried out, consisting of limiting the duration of exposure and rotating workers to minimize private direct exposure times. Normal clinical monitoring and organic surveillance are indispensable for early detection of lead absorption, allowing timely intervention and treatment.

In addition, developing a purification protocol is essential. Workers should follow strict decontamination treatments prior to breaks and at the end of their change to stop lead dust from being carried outside the workplace. This consists of detailed hand and face washing with lead-specific cleaning representatives and altering find here out of contaminated garments.

Precise Clean-up

Keeping a safe job environment extends past employee protection and includes precise cleaning to guarantee lead fragments are completely removed from the site. The procedure of precise cleaning is vital in preventing the recontamination of the moderated area and safeguarding both present and future owners.

To accomplish a detailed cleaning, all job areas have to be systematically sanitized. This involves the usage of specialized HEPA (High-Efficiency Particulate Air) vacuum and wet-wiping methods to record and remove fine lead dust that might have resolved on surfaces. It is vital to cleanse all horizontal surface areas, including floorings, home window sills, and countertops, in addition to vertical surfaces that may have trapped lead fragments.

Workers must use suitable personal protective devices (PPE) throughout cleanup to stay clear of exposure to recurring lead dirt. Made use of cleaning this contact form products such as wipes, sponges, and mop heads must be dealt with according to contaminated materials disposal regulations.

Last Clearance

Final clearance is the vital concluding phase of lead abatement that determines whether the site is safe for reoccupation. This important action includes comprehensive inspection and screening to validate that all lead hazards have actually been efficiently removed.

Last clearance testing not only shields future occupants however likewise makes certain compliance with regional, state, and federal guidelines. Additionally, it offers as a documented recognition of the abatement professional's adherence to sector finest practices. Making certain a comprehensive and effective final clearance is essential in securing public wellness and promoting count on the abatement process.

Final Thought

Ensuring risk-free and thorough lead infraction reduction necessitates a diverse strategy encompassing preliminary analyses with innovative detection techniques, efficient control approaches, strict employee protection protocols, and precise clean-up treatments. The final clearance phase, featuring comprehensive assessments and research laboratory screening, is critical to validate conformity with EPA criteria. Adherence to these ideal methods guarantees a safe environment for occupants, mitigates health threats, and promotes regulative requirements, consequently advertising public health and wellness and safety and security in lead-affected locations.

Report this page